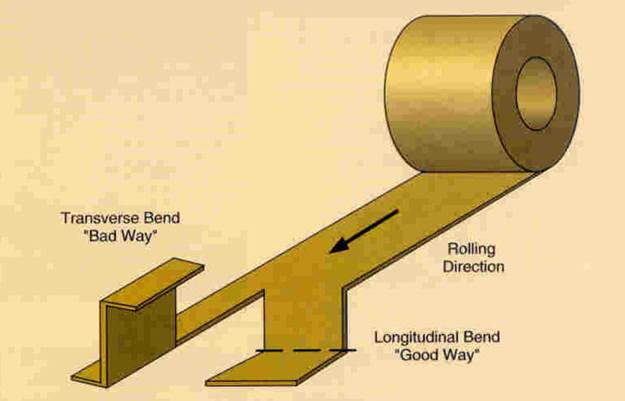

For Bends Perpendicular to the Grain Direction Ratio R/t

- Soft Material, Copper Annealed, CRS .5 to 1.5

- Medium Hard, Annealed Spring Steel 1.5 to 2

- Tempered Material, ¾ hard Stainless >2.5

For Bends Parallel to the Grain Direction

- Consult Material Supplier’s Guidelines